Researchers from Maryland have developed new 3D printing software for creating patient-specific 3D-printed breast phantoms that could help enhance the evaluation of mammography devices, according to an article published in the July issue of the Journal of Medical Imaging.

Clinicians commonly use physical phantoms as surrogates of breast tissue to evaluate the performance of new mammography devices and also assess the quality of existing ones, wrote lead author Andreu Badal, PhD, and colleagues from the U.S. Food and Drug Administration and the University of Maryland. Though this approach allows clinicians to avoid exposing patients to unnecessary mammography radiation, the phantoms typically have a predetermined shape and attenuation, and they do not reproduce the exact size and composition of patients' breasts (JMI, July 2018, Vol. 5:3, 033501).

Seeking to create patient-specific breast phantoms, Badal and colleagues designed an open-source program, mammoreplicator, to convert a standard 2D mammogram into a 3D virtual model that replicates the attenuation of the original mammography image. They used this program to create 3D-printed phantoms based on three mammograms drawn from the U.S. National Institute of Health (NIH) Cancer Genome Atlas.

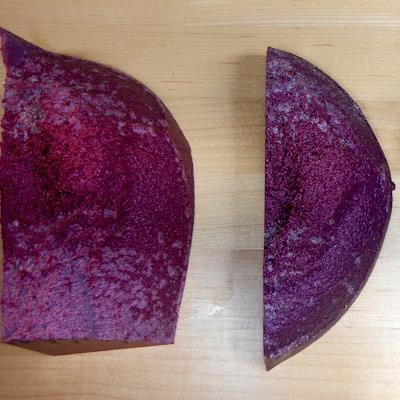

3D-printed breast mammography phantoms. Image courtesy of Andreu Badal, PhD.

3D-printed breast mammography phantoms. Image courtesy of Andreu Badal, PhD.It took the group nearly 10 hours to print each breast phantom with a 3D printer (Objet260 Connex3, Stratasys), and every model required approximately $220 worth of raw materials. The 3D-printed models were composed of flexible (Tango Black Plus), solid (VeroMagenta), or acrylic material (polymethyl methacrylate).

Next, the researchers acquired mammograms of the 3D-printed breast phantoms to assess their similarity to the original mammograms. They found that both new and original mammograms had very close to the same score on the structural similarity quality assessment index, even in regions most susceptible to inaccuracies and increased image noise. They also qualitatively observed that the texture of the glandular tissue, adipose tissue, and microcalcifications were well-replicated in the 3D-printed phantom mammograms.

"3D printing technology can be used to produce patient-specific breast phantoms that can be imaged with clinical mammography systems," the authors wrote. "With the introduced open-source software, researchers can easily create a collection of printed phantoms that reproduce the anatomic variability of real breasts, including varying densities, heterogeneous structures, architectural distortions, and benign and malignant lesions."

The authors suggested that images of these 3D-printed breast phantoms could help clinicians evaluate the quality mammography devices and allow them to generate individually tailored mammograms for presentation.