Anyone who reads our articles knows that MRI facilities require special attention in design and construction. The magnets weigh too much, the magnetic fields are too strong, and the equipment is so integral to patient care that building a new suite requires expert attention. But everyone may not be aware that construction outside the MRI suite can incapacitate the magnet, even damage its imaging capabilities.

Magnets can be highly sensitive to vibration, changes in the amounts of ferrous materials (steel) nearby, and highly susceptible to interference from moving metal objects. So, even if a planned expansion is adjacent to the MRI and not inside the suite, extra consideration is needed to protect the operation of this equipment.

Consider the vibration from sawing, jackhammering, drilling, and other typical construction activities. Even if it happens across the hall, the vibration from these activities can be transmitted through the structure of the building to the magnet suite. These vibrations, when conducted to your MRI, can impair the images and make some longer or more sensitive scans virtually impossible to acquire.

But the sources of vibration need not be within the building to incapacitate a couple million dollars of imaging equipment. Construction work outside, including excavation, drilling, demolition, and driving pilings are just a few ways that a contractor working outside the building can generate enough vibration to disrupt scanning. These vibrations can travel underground, shaking the very soil the building sits on, and can incapacitate the MRI just as work within the building can.

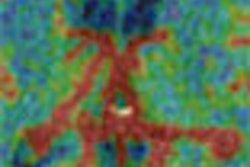

Vibration, unfortunately, isn't the only hazard to MRI operation that construction poses. Ferrous masses, from backhoes to 2-ton steel girders, down to a pile of light-gauge metal studs, are constantly changing and moving around magnets during construction. These changing and moving metal masses disrupt the magnetic field and distort the machine's sensitivities.

One technologist shared a story with us of a construction project outside his MRI suite. He carefully staked out the area outside the magnet room, and informed the contractor that they were not to bring any heavy equipment inside that area or they would disrupt patient scans.

A couple weeks later, conducting a MR spectroscopy exam on a patient, he got wildly aberrant results. He walked outside the MRI suite and found that a subcontractor had piled a stack of lightweight steel studs, used to frame walls, against the outside of the magnet room. This change in ferrous mass was enough to significantly throw off the scan, showing that it doesn't take bulldozers or backhoes to disrupt patient care.

Steel shields, designed to restrain the spread of magnetic fields, can help attenuate the sensitivities to moving metal alongside the MRI suite, but can ironically increase a magnet's relative sensitivity to moving metal in certain locations. A steel shield acts as a conduit, allowing magnetic energy to pass through it instead of through the air around it. An MRI that is provided with steel shielding only in the walls will have a disproportionate sensitivity to metal disturbances above and below.

So while you may be able to park a 100-ton crane near your MRI suite without consequence, you might not be able to use it to swing a couple hundred pounds of steel anywhere within 30-50 feet of the roof of the magnet room. This sensitivity will vary significantly depending upon both the magnet system and shield configuration.

Contemporary construction is remarkably precise, when provided with precise information to work from. Unfortunately, accurate drawings of which power lines are buried where, or where a pipe goes to or comes from, seem to always be notoriously absent. Renovation and expansion projects often happen with the occasional "Oops," when conduits are inadvertently cut or buried pipes broken.

When a severed conduit or broken pipe serves the MRI, the consequence can be unanticipated downtime. Even when every inch of pipe and strand of wiring is located, neighboring projects can require interruption of services. When anticipated, these interruptions can be coordinated to minimize their impact. When accidental, they can require days or weeks to remedy.

If power to an MRI is severed, it is imperative that it be re-established. Depending on the magnet, the onboard cryogens in superconducting systems can reach a critical boiling point in two to five days, spontaneously quenching. Apart from the loss of thousands of dollars of cryogens, the thermal shock to the magnet that comes from rising 500 degrees can cause irreparable structural damage to the magnet.

Even if a construction project is perfectly planned and executed so as to not interrupt the operation of the magnet, there is the parallel issue of access to the building. Even if the MRI is fine, is it best to bring patients through a construction zone to enter a facility? Depending on the circumstances, patient access may be a greater factor in crippling a MRI's operation during construction.

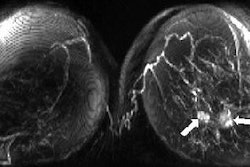

Once the construction is done, the backhoes are gone, and the construction workers have moved on to the next job, there may still be unpleasant surprises awaiting you. Particularly for wood-framed buildings that tend to be more flexible than their steel and concrete counterparts, adjacent construction activities may have caused minuscule amounts of building movement. For nearly every other function, except MRI, this would be imperceptible and without consequence. However, repeated small movements in a radiofrequency (RF) shield can cause joints to fail and create RF leaks. Shield leaks erode the signal-to-noise ratio vital to effective clinical MRI.

For facilities contemplating construction projects near an MRI, here's an abbreviated checklist of issues to consider:

- Unshielded high-field magnets can be more sensitive to changes in ferrous masses and moving metal outside the magnet suite.

- If power is cut to a superconducting magnet, the magnet can quench if power is not restored within a couple of days.

- Open MRI units with a cantilevered upper magnet, supported from only one side, can be much more susceptible to vibration interference than other open MRI systems.

- Vibration that is either too strong or sustained for too long can initiate a quench.

- Keep construction equipment and materials away from magnet rooms, including areas immediately outside the building.

- Magnetic pinch shields can increase the relative sensitivity to ferrous materials above and below a magnet.

- Vibrations from digging/drilling foundations can be transmitted both through the building as well as underground, so construction doesn't have to be right next to the MRI to disrupt it.

- Have a contingency plan. What if MRI is unusable for days, weeks, or months? Hopefully you won't have to use a contingency plan, but it is better to be safe than sorry.

- Heed technologists' reports of compromised images, as the magnet or RF shield may require a service call after construction.

By Robert Junk and Tobias Gilk

AuntMinnie.com contributing writers

June 9, 2005

Reprinted from www.mri-planning.com by permission of the authors. If you would like more information on any aspect of MR facility design or safety, please contact Robert Junk or Tobias Gilk at Jünk Architects.

Related Reading

Part II: Answers to the 10 questions to ask your architect about MRI suite design, April 7, 2005

Part I: 10 questions to ask your architect about MRI suite design, April 5, 2005

The 3-tesla MRI swap: Why it's not a simple upgrade, January 27, 2005

Chilled loop failure: How to break your magnet without even trying, December 8, 2004

HIPAA compliance strategies for MR control rooms, October 26, 2004

Copyright © 2005 Jünk Architects, PC