What's the old joke about the similarity between doctors and general contractors? Both bury their mistakes!

When we walk into an MRI suite, the rooms don't look all that different from other parts of the hospital or imaging suite. But the fact is that those similarities are only superficial. The parts of the MRI suite construction concealed behind the wallpaper or under the floor tiles should be significantly different from traditional construction. The fact that the outward appearance can be made to look so similar means that egregious construction errors that degrade image quality can remain hidden for years, if not decades.

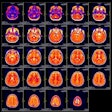

And it's not a situation in which out of sight means out of mind. Construction errors or shortcuts can significantly impair the clinical operation of an MRI unit, reduce image quality, and shorten the economic life of an MRI installation. All other things being equal, an MRI that has inferior image quality may be suffering from a poorly designed and built suite, though you can't tell simply by looking at the wallpaper or floor tile.

Shim tolerances

Many MRI vendors have improved the capability to shim magnets to correct for greater and greater masses of steel in the MRI suite. This has facilitated the recent siting of magnets in spaces that, only a few short years ago, would have been deemed unsuitable. Buildings built with heavy steel frames, or even conventional steel rebar, are potentially viable to host MRI suites. This increased flexibility, however, comes at a price. Heavily shimmed magnets often have a distorted "sweet spot," that compromises image quality, particularly for anatomy not centered in the bore, such as shoulders.

RF leakage

A poorly constructed radio frequency (RF) enclosure also degrades image quality, but even a perfectly constructed RF shield can be compromised by poor suite design or construction. Differential movement is when a building settles at different rates in different places. Any building movement has the potential to damage the RF shield, but differential movement, which may be triggered by 12-ton magnets and inadequate structural supports, can cause even greater damage to an RF shield.

Vibration isolation

Vibration, whether from external sources (such as roadways, trains, and so on) or internal sources (pumps, hoists, motors, and the like), can be seriously disruptive to an MRI scan. From expansion joints to "floating slabs" to vibration dampening systems, there are a number of ways to protect against vibration and preserve the optimal image quality for a magnet.

Unfortunately, using nonferrous structural members, providing additional shoring to prevent even slight differential movement, and installing vibration-resisting techniques are not standard means of construction. It usually requires an architect and a contractor, each of whom go beyond the call of duty and understand what the specialized construction of an MRI suite is supposed to achieve. Shortcuts, or even "standard" building construction techniques developed for non-MRI construction, can silently impair an MRI system.

Here's where it all comes together. It isn't simply about making a box into which you can place an appliance. Image quality, patient throughput, and, ultimately, both clinical quality and financial performance are tied directly to the quality of the MRI suite design and construction.

As a result, there will always be technologists complaining to their administrators, administrators screaming at MRI vendors, and vendor engineers scratching their heads while running a gamut of diagnostics to try and determine why image quality is not up to par. All of this will happen, again and again, because MRI suite construction is fundamentally different from that of typical buildings, and this lesson will only be learned the hard way by many cut-and-paste designers and one-pickup-truck contractors.

But the hardest lessons -- the ones that translate into many, many dollars of lost revenue -- will be reserved for the diagnostic imaging center operators who entrusted a million-dollar MRI to novices. And without the ability to see through the walls and floors to uncover the problems built in to their suite, they may not learn much from the experience, except how to write checks with more and more zeros at the end.

By Tobias Gilk

AuntMinnie.com contributing writer

November 23, 2005

Reprinted from www.mri-planning.com by permission of the authors. If you would like more information on any aspect of MR facility design or safety, please contact Robert Junk or Tobias Gilk at Jünk Architects.

Related Reading

The new 'MR Safe': Language changes for the FDA, October 27, 2005

Cost of MRI mishaps makes safety investment profitable, October 14, 2005

Interim trailer leasing: The hidden cost of MRI suite renovations, September 28, 2005

A shocking story of MRI static discharge, September 21, 2005

DI in the OR: The advent of intraoperative imaging, August 31, 2005

Copyright © 2005 Jünk Architects, PC