It's nice to know that radiology has a higher calling -- somewhere around 35,000 feet in the air. Advanced imaging technologies based on CT and MRI are now being used to protect the lives of airline passengers as well as patients. In the wake of last month's terrorist attacks in the U.S., the companies that build these systems have earned the attention of flyers, and a rush of new orders.

One by one, the x-ray baggage screening systems used in airports since the early 1970s are giving way to CT-based explosives detection systems (EDS) equipped with advanced computer-aided detection features. In 1994 the first generation of these new systems began to be deployed at airports around the world, screening both checked and carry-on luggage before the planes leave the ground. In the past six weeks, demand for the devices has also soared.

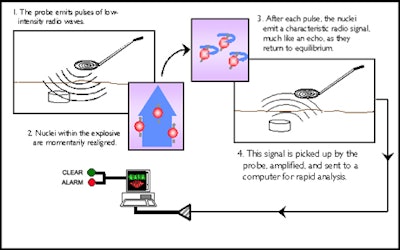

A different kind of EDS system specializes in chemical-specific explosives detection using equipment similar to MRI. So-called quadrupole resonance devices emit a series of frequency pulses to read the unique properties of dozens of explosive materials. Proprietary algorithms in the software analyze the altered frequencies that bounce back. The calling cards of these substances cannot be concealed, according to the manufacturer, which targets new explosives for detection as they are developed.

InVision Technologies of Newark, CA leads the field in EDS, with 260 CT-based systems installed worldwide, including 140 at U.S. airports. The firm's wholly owned subsidiary, Quantum Magnetics of San Diego, CA, manufactures the MRI-related devices, including automatic weapons and plastic explosives detection systems for checked luggage and mail sacks, and landmine detectors based on the same technology.

Tragedy at Lockerbie

Research on EDS systems began in the aftermath of the 1988 crash of Pan Am flight 103 over Lockerbie, Scotland. Investigators determined that a bomb in the luggage compartment had exploded in mid-air, causing a crash that killed all 259 passengers on-board, and 11 others on the ground.

The crash was the catalyst for a new law in the U.S.: the Aviation Security Improvement Act of 1990, aimed at improving the efficiency of EDS used in airports. To accomplish that goal, the act authorized grant funding to several companies for use in developing EDS that were sensitive and reliable enough to receive certification from the U.S. Federal Aviation Administration (FAA). The agency hopes to screen 100% of luggage by 2009, with a high percentage of the systems online long before then.

InVision was among a handful of firms that received U.S. government funds in 1990 to develop EDS technologies. In 1994 it became the first of only two companies to build FAA-certified EDS products. InVision says it now manufactures and maintains more than 90% of installed CT-based EDS, which are the only systems currently authorized for certification.

In November 1998, L3 Communications of Coldwater, FL, became the second company to receive U.S. approval, for the eXaminer 3DX 6000 EDS system it developed in conjunction with Analogic of Peabody, MA. The device features Analogic's dual-energy-capable, helical-cone-beam, multislice Exact CT scanner. Detection algorithms for sheet-like forms of explosives were also developed by Analogic.

Using CT to detect explosives

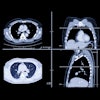

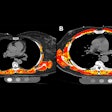

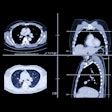

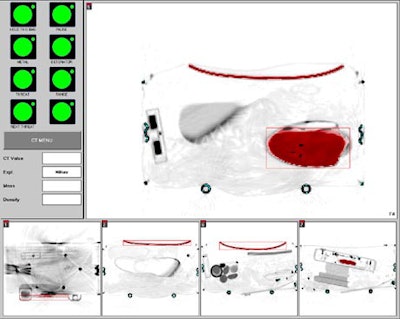

InVision's 3 CT-based systems range in cost from $500,000 to about $1.5 million. Its top-of-the-line CTX 9000 can handle 542 bags an hour. As luggage moves through the scanner on a conveyor belt, image data slices are acquired using a rotating x-ray source similar to that used in a medical CT scanner, according to Yotam Margalit, the firm's director of product development.

"First we generate a regular two-dimensional projection image of the bag, and then the computer scans [the image] and looks for areas of high attenuation, or areas of interest based on other algorithmic tricks -- not just the darkness of that specific area," Margalit said.

The proprietary software functions as a kind of CAD system that assesses the image in two passes through the scanner. Along with density, it looks for certain shapes, patterns, and combinations that are kept secret and updated continually in cooperation with the FAA.

"[The software] uses a regression tree that adds up the values of a set of measurements and various characteristics found by a series of algorithms which look for elements found in real bombs, and then basically scores them out by the highest probability first," Margalit said. Then the scanner zeroes in on previously located areas of interest for the second pass.

"It will then go and slice those areas up, this time making cross-sectional images in which we calculate the density of specific voxels inside the bag, basically reconstructing the cross-sectional images and remeasuring the density," he said. "If the density of those voxels is similar to that of explosives, it will calculate mass."

When the characteristics add up to a certain FAA-classified threshold score, an alarm sounds, and the object is displayed on the screen along with its estimated weight, location, and average density, Margalit said. Humans take over from there.

|

Lee McPherson is a California-based manager with Mercury Computer Systems of Chelmsford, MA, which builds the computers used in InVision's CT-based detection systems. The essential difference between computing systems used in medical CT applications and those used in airport security is processing power, he said. InVision's EDS systems use the equivalent of 2-4 Motorola G4 processors, about a quarter of the processing power used in medical applications, he said.

Quadrupole resonance devices

In 1997 InVision acquired Quantum Magnetics of San Diego, CA, as a wholly owned subsidiary. QM specializes in detecting chemical-specific explosives, with devices that can be used alone or in combination with CT scanners.

Quantum Magnetics' QScan products are designed for airports and other facility security applications. The technology is similar to MRI, but lacks a magnet in order to avoid damage to videotapes, disk drives, or similar devices. The low-intensity radiofrequency pulses it emits are nonmagnetic, chairman and CEO Lowell Burnett, Ph.D. told AuntMinnie.com.

"When you do an MRI, you have a certain characteristic frequency, a nuclear magnetic resonance frequency, determined by the strength of the magnetic field. So the stronger the field, the higher the frequency," Burnett said. "In quadrupole resonance, there are certain nuclei that have magnetic resonances that occur at zero external [magnetic] field."

The specific resonances are determined by two molecular characteristics: the strength of the electromagnetic field and the site of the nuclei. These fields are what hold the molecules together, and of course remain even when the magnet is turned off, Burnett said.

"Essentially, we're doing MRI without the magnet -- with zero field. And the resonances come from the fields that are internal to the molecule," he said.

|

QM's products, including iPortal passenger screeners and QScan package and baggage scanners, are based on the principle that the molecules that form each kind of explosives material are chemically distinct, and thus produce distinct magnetic fields. In response to carefully tuned low-intensity wave pulses, each distinct molecular structure reflects a unique set of quadrupole resonance frequencies.

"We get very different quadrupole resonance characteristics from, say, TNT than we do from Semtex, or C4 plastic explosives," Burnett said. "And what that means is you get a very low false-alarm rate. Because if you look for the resonance of a plastic explosive, say Semtex, there are very few molecules that have similar electromagnetic fields holding them together."

The computer simply looks for the characteristic signal of explosives. If there's a match, the system flashes a red light rather than a green one. The systems are in use at airports throughout the world, although QM doesn't generally disclose where they are located.

Quadrupole resonance technology was originally developed at the U.S. Naval Research Laboratory in Arlington, VA, and given to QM to engineer the products. In 1997 the company shared the Innovative Project of the year award from Aviation Week and Space Technology, according to parent firm InVision.

Along with the aviation security devices, QM has received contracts totaling $30 million this year to develop a quadrupole resonance-based vehicular landmine detection system for the U.S. Army.

Catching up

At an electronic news conference Wednesday, InVision announced its fifth consecutive profitable quarter (end-September 30), although Q3 revenues declined 11.2%. For the period (end-September 30), the company had revenues of $51.3 million, compared with $57.8 million in the same quarter last year.

InVision had net income of $447,000, compared with net income of $197,000 in the third quarter of 2000. The firm has been investing heavily to increase production -- in response to both surging demand, and questions about the firm's ability to meet it, said president and CEO Sergio Magistri.

InVision is moving toward 24/7 production of the devices, which will enable it to triple production to about 30-40 EDS systems per month, he said.

"We are positioned well going into the fourth quarter, with a backlog of $42 million, including $24 million in EDS systems and services," Magistri said. "We also have a rapidly growing pipeline of EDS orders in negotiations."

By Eric BarnesAuntMinnie.com staff writer

October 26, 2001

Copyright © 2001AuntMinnie.com