Researchers from Australia and China have created a 3D-printed heart that mirrors the size and texture of real cardiac tissue, with potential clinical applications in patient and medical education, communication among clinicians, and presurgical planning, according to a recent study published in PLOS One.

The investigators used rubber-like material to 3D print a heart model based on coronary CT angiography (CCTA) of a 20-month-old patient with congenital heart disease (CHD). They found that the model not only accurately represented scans of the patient's heart but also could be beneficial for planning the necessary interventional procedure and educating the parents (PLOS One, March 21, 2018).

"The flexible 3D-printed heart model can be accurately reproduced from cardiac CT images," wrote senior author Dr. Zhonghua Sun and colleagues from Curtin University in Perth and Capital Medical University in Beijing. "It is found to facilitate preoperative planning and improve the surgical outcome; enhance patient-doctor and interprofessional communication; and improve approach in medical teaching."

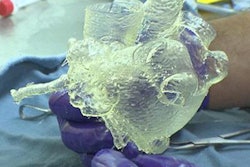

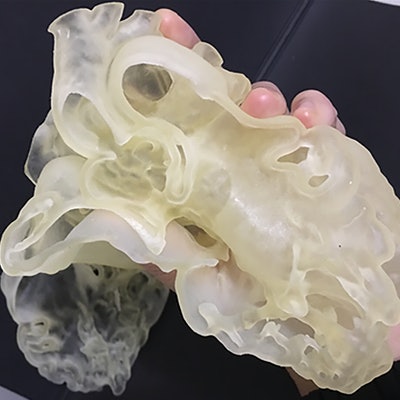

Demonstration of the flexibility of a 3D-printed heart made of TangoPlus material. All images courtesy of Dr. Zhonghua Sun.

Demonstration of the flexibility of a 3D-printed heart made of TangoPlus material. All images courtesy of Dr. Zhonghua Sun.Flexible 3D-printed heart

In recent years, physicians have been using 3D-printed models of the heart to facilitate diagnostic assessment and preoperative planning -- particularly for complex pediatric cases such as CHD, according to the authors. These models can provide clinicians and patients with a more complete 3D spatial visualization of the heart and surrounding structures, compared with the traditional method of examining CT scans, MR images, or echocardiograms.

Seeking to enhance the realism of such 3D-printed models, Sun and colleagues created a 3D-printed heart using flexible material that more closely resembles cardiac tissue than the typical rigid 3D printing material.

Initial digital models were based on the CCTA scans of five CHD patients younger than 15 years. The researchers modified these scans to create the digital 3D models and then processed them following a series of steps:

- Isolate key anatomical structures and threshold with segmentation software (Mimics Innovation Suite, Materialise).

- Smooth and hollow the model.

- Add an arbitrary 2-mm-thick layer to the model's surface to represent the heart wall using editing software (3-matic, Materialise).

- Divide the model into two compartments in 3D software (Geomagic Studio 12, 3D Systems).

Once the digital models were edited, the group chose one of the models to print with a commercial PolyJet 3D printer (Objet Eden 260VS, Stratasys) using flexible, rubber-like material (TangoPlus). Generating the digital 3D model took two hours, postprocessing it took 15 minutes, and the final 3D-printed model cost an estimated $232.

Next, Sun and colleagues used contrast-enhanced CT on the 3D-printed heart and collected the internal diameter of 10 anatomical locations on the resulting CT scans using the ruler function of a DICOM viewer (Horos, Horos Project). They compared these diameters with those of the originating CCTA scans to verify the accuracy of the 3D-printed heart.

Measurements of each of the 10 regions on the 3D-printed heart had a strong correlation (r = 0.99) with those of corresponding locations on the original scans. Overall, the 3D-printed model slightly overestimated the size of the heart by an average of 0.23 mm in each area.

Virtual heart model (left) and 3D-printed heart (right).

Virtual heart model (left) and 3D-printed heart (right).Useful for planning, education

To assess the clinical value of the flexible 3D-printed heart, the researchers conducted interviews and surveys of two radiologists, two cardiologists, two cardiac surgeons, and three members of the medical academic staff. Six out of nine had prior experience using 3D-printed hearts, and their average satisfaction score for the model was 8.4 out of 10.

Among the six physicians, four reported that the 3D-printed model could be useful in planning procedures, and three said it could be useful in testing devices for presurgical simulation. The rest said it may be useful for these purposes, and none claimed it was not useful.

All of the cardiac surgeons and cardiologists agreed that the 3D-printed model could be useful in enhancing patient-doctor communication and would be "invaluable" for improving the efficiency of consultation in terms of knowledge gained. Only half, though, thought using the model would save time. Four out of the six health professionals indicated their preference for using a combination of medical images and 3D-printed models to communicate with patients or other clinicians.

This result suggests that 3D-printed models might serve as a complementary tool in patient-to-doctor and clinician-to-clinician communication, rather than replace existing approaches, the authors noted.

Regarding medical education, the academic staff members said using 3D-printed hearts would help the students "be able to learn the pathology quicker with better understanding," the researchers wrote.

"Overall, the cardiac surgeons and cardiologists responded positively with respect to the use of the 3D-printed heart model in communication within medical practice," they wrote. "These positive findings are significant, as this is the first report to investigate the accuracy and the multidirectional utility of the 3D-printed heart model in a holistic approach."

A major limitation of the study was that the readers measured select regions of the CT scans of the 3D-printed heart only in the axial plane, according to the authors. They acknowledged the need for measurements in the coronal and sagittal planes as well as the need to assess the dimensional accuracy of the model in continuing studies more comprehensively.

"As 3D printing in cardiovascular specialty is still in its infancy, future studies should include more cases and participants to confirm the dimensional accuracy and clinical value of the 3D-printed heart models," they wrote. "Furthermore, future investigations should also focus on analyzing the cost-benefit of 3D printing of CHD."