Creating 3D-printed models of fractured mandibles may reduce time spent in the operating room (OR), according to a new study in JAMA Facial Plastic Surgery. The findings suggest that inexpensive 3D printing technologies could save hospitals hundreds of dollars per operation.

Advancements in technology have reduced 3D printing costs and times, and researchers from the Washington University School of Medicine in St. Louis wanted to know whether 3D printing could be also used to preoperatively plan for surgeries to repair complex, mandibular fractures. They found that 3D-printed mandibular templates can be made in hours for just a couple hundred dollars.

"Our feasibility study demonstrated that patient- and site-specific 3D-printed short-segment mandibular templates can be created to facilitate preoperative planning within hours and at a very low cost," wrote the authors, led by Parul Sinha, MD, a postdoctoral scholar from the medical school's department of otolaryngology -- head and neck surgery (JAMA Facial Plastic Surgery, April 26, 2018).

The 3D printing process

Complex fractures sometimes require metal plates to hold and support bones while they heal and beyond. Surgeons are increasingly using complete, perfected 3D-printed mandibular models to bend these plates before surgery. However, a perfected, mandibular template can cost thousands of the dollars and take weeks to print, making the technology unfeasible for complex fractures that require more immediate repair.

“Our feasibility study demonstrated that patient- and site-specific 3D-printed short-segment mandibular templates can be created.”

Therefore, the researchers were curious whether smaller, short-segment templates could be 3D printed within the time requirements for these complicated fractures. They decided to test their hypothesis with a small, feasibility study.

"Our objective was to explore the theoretical and practical applications for rapid, inexpensive 3D printing of a short-segment mandibular template prototype in mandibular fracture repair," the authors wrote.

They used unidentified CT scans of three patients who had complex fractures, either comminuted or displaced mandibular fractures. From the CT scans, the researchers created two types of models:

- A perfected mandibular model

- Six, short-segment templates of the right and left angle, body, and symphyseal/parasymphyseal segments

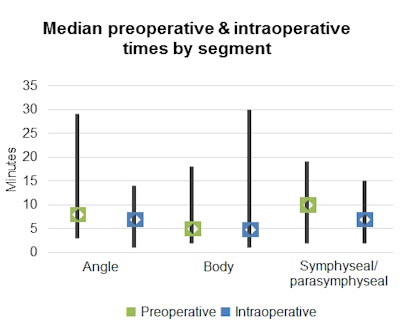

Once both types of templates were printed, the researchers moved onto the testing phase of their study, which consisted of preoperative and intraoperative sessions. In the first preoperative part of the study, first- and second-year postgraduate residents at the Washington University School of Medicine bent mandibular fracture plates using the 3D-printed short-segment mandibular templates. This simulated how long it would take the residents with little knowledge of mandibular fracture plating to preoperatively bend plates.

In the second intraoperative part of the study, the same residents used the perfected, complete mandible model to bend fracture plates. The researchers used the model as a representation of what the residents would see during surgery so that they could estimate intraoperative plate bending times.

Estimated cost and time savings

Overall, it took about 5.5 hours and $200 to both model and print six, short-segment mandibular templates. By comparison, the cost of a complete, perfected model from an outside company can range from $2,000 to $6,000, according to the authors.

The residents also generally completed the intraoperative part of the study faster than the preoperative part of the study. The time saved ranged from one to 30 minutes depending on the segment and the resident, but even a few minutes shaved off surgery in the operating room could save hospitals hundreds of dollars, the authors noted.

"The median OR charge equivalent ($50.05/min at Barnes Jewish Hospital) of the intraoperative times was $350.35, $250, and $350.35 for the angle, body, and symphyseal/parasymphyseal segments, respectively," they wrote.

Research still needed

It is important to note that the plates bent by the residents were only used for the purpose of the study and were not used on patients. Furthermore, since this was only a feasibility study, the operative time savings are merely projections and not representative of how the technology would perform when used in an actual surgery. The researchers also did not account for the time surgeons would need to learn how to use 3D modeling software and techniques.

Nevertheless, the study findings show promise that 3D-printed short-segment templates may reduce intraoperative times for mandibular fracture repair. Future studies will need to continue investigating whether this technology can shorten operating times and reduce costs.

"The 3D-printed short-segment mandibular templates facilitate preoperative plate contouring in a fashion similar to the perfected mandible models and have the potential to reduce operative times," the authors concluded. "However, a reliable estimation of the OR cost and time will require further studies in actual patient care."