A study of more than 500 MRI performance evaluations conducted over 10 years has found that 78% of all MRI scanners have image quality problems, and 25% of all multichannel radiofrequency (RF) coils have a least one bad channel.

The study, conducted between August 2001 and March 2011 on more than 204 magnets from eight vendors, found deficiencies that included improper configuration, an inability to scan, failure of one or more channels, a year-to-year decrease in signal-to-noise ratio, and ghosting. In addition, approximately 17% of MR magnets evaluated had homogeneity problems.

The research was led by Moriel NessAiver, PhD, whose simplyphysics.com website provides information on MRI accreditation services, education, and safety issues.

Imaging background

NessAiver has worked in the field of MRI since 1985, when he began his career with the former Israeli medical imaging firm Elscint. He later moved to Picker International, where he headed the company's cardiac MR research program for five years. Following his stint at Picker, NessAiver conducted research and taught for 10 years at the University of Maryland, during which time he wrote a textbook on MRI physics.

After the book's publication, he was asked by the American College of Radiology (ACR) to perform reviews of phantoms for the ACR's accreditation program. Six months later, the ACR asked him to join its physics MR subcommittee for accreditation.

Approximately 11 years ago, he began to research appropriate strategies to ensure MRI quality assurance above and beyond the ACR guidelines. He also developed software to automate the process of quality assurance and quality control, and he created a database that currently holds more than 11,000 records detailing his onsite MRI experiences.

"The ACR requires that [a facility] have a medical physicist do the annual performance evaluation," NessAiver said. "Most medical physicists are very well-trained individuals in nuclear medicine, CT, mammography, and x-ray. They don't know anything about MR."

The main issue, he believes, is that MRI is much more complex "than all the other imaging modalities combined. With MR, you have T1, T2, inversion recovery, gradient echo, fast-spin echo, echo-planar imaging, contrast imaging, parallel imaging, single coil, phased-array coil -- all these different things all work together," he said. "In CT, you have 16 channels and the dosage. It is not much more complicated than that."

MRI technology has also become more sophisticated as more phased-array channels are added to create more detailed images. The complexity of the technology expands exponentially, as does the chance of an equipment problem.

"The ACR manual was a supremely written document when it was written 12 years ago," NessAiver said. "It wasn't until I actually started implementing what was in there that I realized it was missing things."

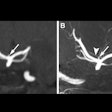

The most valuable lesson from years of evaluation is the need to test every channel of every phased-array coil, NessAiver said. His study, presented at the RSNA 2011 annual meeting, noted that to calculate signal-to-noise ratios, the ACR's manual recommends drawing a circle that contains 80% of the phantom for volume coils. However, for other coils, the ACR recommends positioning a small, circular region of interest on top of the area of greatest signal.

That strategy works if the coils are functioning properly, NessAiver said. However, small changes in positioning can occur over time, and if one channel is not working properly, the maximum signal will be in a different location at the time of the next evaluation and could adversely affect quality assurance results.

Bad channels

After finding problems at the majority of MRI sites he visited, NessAiver started to gather statistics on the faults.

"I was finding bad channels in phased-array coils in 18% of the coils I tested," he said. "That number is up to 25% now, because more and more coils have more and more channels. The greater the number of channels, the greater the likelihood of a problem."

To address the issue, NessAiver developed software to detect and measure signal automatically over the entire phantom. That way, if peak signal in the coil changes its location, each coil channel is evaluated the same way.

"The key for quality control is to do the same thing from year to year, from system to system, and from channel to channel," he emphasized. "Quality control is in consistency. It is impossible to be consistent by manually placing a region of interest somewhere in the middle of the image."

NessAiver advises that medical physicists test each individual channel for every phased-array coil on a yearly basis. "Ask your physicist if he knows how to do that," he added. "If he is not testing the channels, he is not doing a proper job."

NessAiver also suggests not relying completely on a manufacturer's quality assurance specifications because they are "very general." The specifications "are made so that when a system is first installed, it will pass," he said. "They do not look for year-to-year variation. A 10% to 15% drop from one year to the next is still within specifications."

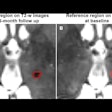

Magnet homogeneity

Another important factor in quality assurance is magnet homogeneity. Poor magnet homogeneity can result in geometric distortion, and it can make it difficult to perform fat saturation and to take advantage of advanced techniques such as echo-planar imaging or 3D balanced gradient-echo imaging, NessAiver noted.

"Out of the 534 yearly performance evaluations, 61 systems were found to have homogeneity issues," according to NessAiver. "Sometimes the problem was simply metal in the magnet bore. Other times the supercon shim currents had drifted."

One important factor to consider in ensuring proper magnet homogeneity is phantom selection. NessAiver recommends a uniform sphere -- the larger the better -- to measure the largest volume. He cited GE Healthcare's 31- or 32-cm sphere, depending on the MR system; Siemens Healthcare's 24-cm sphere; and Philips Healthcare's 38-cm wide disk that is 10-cm thick, for magnet homogeneity.

Using his own software, which measures magnet homogeneity across a 32-cm sphere, NessAiver said he has found magnet homogeneity problems about 11% of the time.

In summary, NessAiver said the most important factor in MRI quality assurance is "to test every channel of every coil. You must have a physicist who knows how to do that, and who knows how to independently verify magnet homogeneity."