The combination of percutaneous nephrolithotomy and 3D-printed models produced from patient CT scans enables significantly better treatment of complex renal calculi, or kidney stones, according to research published January 10 in Scientific Reports.

Researchers from the Air Force Military Medical University in Shaanxi, China, assessed the use of 3D-printed models for patient communication and planning of percutaneous nephrolithotomy and compared the results with patients receiving only traditional percutaneous nephrolithotomy. They found that the patients in a group that received 3D-printed models experienced significantly better doctor-patient communication, faster operations, a higher calculi clearance rate, and reduced complications.

"The proposed method is thus a safe and effective method to treat complex renal calculi," wrote the study authors led by co-first authors Dong Cui, Fengqi Yan, and JiangPu Yi.

Although percutaneous nephrolithotomy guided by traditional B-mode ultrasound or x-ray yields good results for treating simple renal calculi, the method has a high complication rate for complex kidney stones, according to the researchers. As a result, they sought to perform a prospective randomized controlled study to evaluate the therapeutic effect of combining 3D printing with percutaneous nephrolithotomy in these patients.

In a study performed between May 2017 and May 2021, 90 patients with complex renal calculi were randomly placed into either a 3D-printing group or a control group. The 45 patients in the 3D-printing group had an average body mass index of 24.3 and a mean kidney calculi diameter of 3.81 cm, while the control group had a mean body mass index of 23.21 and an average kidney calculi diameter of 3.60 cm.

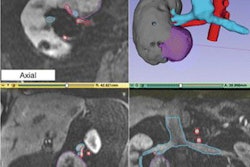

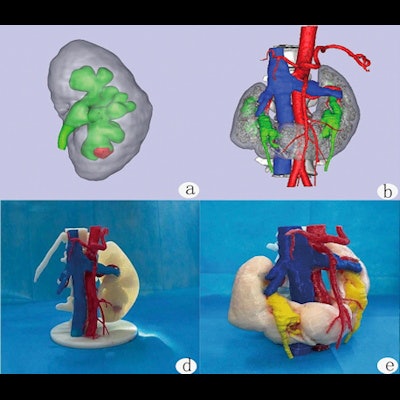

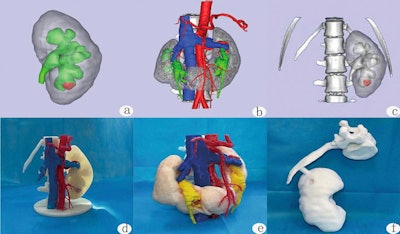

The authors used Mimics 17.0 software (Materialise) to process thin-slice CT images of the patient's kidneys. Next, they combined 3D-reconstructed images of the different parts of the kidney into a complete kidney image. They also reconstructed the 11th and 12th ribs together before producing a standardized stereolithography (STL) file for 3D printing.

After a puncture point was drawn on the image, the researchers then designed the best puncture channel, depth, and track in the combined 3D image. In the final step, they printed a 3D model on a rs4500 3D printer (Shanghai liantai Technology).

Puncture training and postoperative plain film. (a) Selection of puncture sites and calyces in a 3D reconstruction image; (b,c) puncture training, target calyces, selection of puncture angle, and estimation of puncture depth on 3D-printed physical model. (d) Postoperative plain film. Images and caption courtesy of Dong Cui, Fengqi Yan, JiangPu Yi, et al, and Scientific Reports through Creative Commons Attribution 4.0 International License.

Puncture training and postoperative plain film. (a) Selection of puncture sites and calyces in a 3D reconstruction image; (b,c) puncture training, target calyces, selection of puncture angle, and estimation of puncture depth on 3D-printed physical model. (d) Postoperative plain film. Images and caption courtesy of Dong Cui, Fengqi Yan, JiangPu Yi, et al, and Scientific Reports through Creative Commons Attribution 4.0 International License.In the 3D-printing group, these 3D-printed models were used for doctor-patient communication, as well as percutaneous renal channel design, percutaneous renal puncture, and intraoperative guidance. Patients in the 3D-printing group were treated under the guidance of the 3D model and B-mode ultrasound, while the patients in the control group were treated with the conventional puncture method guided by B-mode ultrasound, according to the researchers.

Patients in both groups were also surveyed to rate the communication they received from their physician on the procedure.

| Improved complex renal calculi treatment from use of 3D printing | ||

| Control group | 3D-printing group | |

| Overall score of doctor-patient communication objects | 14.51 | 19.32 |

| Mean operation time | 126.1 minutes | 103.2 minutes |

| Calculi clearing rate | 80% | 96% |

| Incidence of postoperative complications | 22.2% | 6.7% |

"Compared with traditional percutaneous nephrolithotomy, 3D printing technology combined with percutaneous nephrolithotomy can significantly enhance the effectiveness of doctor–patient communication, shorten operation time, reduce operation bleeding, improve the stone clearance rate, reduce the incidence of complications and shorten the length of hospital stay," the authors wrote.

The researchers noted, though, that the combination of 3D printing and percutaneous nephrolithotomy in kidney stone treatment still requires further research and development.