Last year we watched 24-hour news channels in fascination and horror as Hurricane Katrina lashed the U.S. Gulf Coast. Those of us who don't live on the coast between Texas and South Carolina counted ourselves lucky that we weren't there, as we do every time the Weather Channel covers a major storm. Although they weren't feasted upon by the cable news networks, the medical community had no shortage of stories to pass around about MRI equipment damaged or destroyed by mean and nasty weather -- and the domino effect on healthcare providers.

Does that mean that those of us without a beachfront view are safe from having our MRI equipment battered by inclement weather? No! In fact one of the most common quench pipe installation details -- in place at MRI units across the country -- can jeopardize million-dollar magnets. For superconducting MRI systems with this cryogen vent discharge detail, the combination of wind-driven rain and a sustained power failure or intentional quench can lead to a catastrophic failure, destroying your MRI equipment and jeopardizing patients and staff.

In many superconducting MRI installations, if as little as a drinking-glass amount of water were to enter the quench pipe, it would collect on top of the pressure-relief valve of the MRI's cryostat and at least partially cover that part of the valve that is supposed to burst outward in a quench event. Having watched weathercasters hanging on for dear life as torrential rains are whipped around in hurricanes, it's easy to understand how such conditions could drive rain water into places it wouldn't otherwise get to (such as your quench pipe), but our investigations uncovered that it takes substantially less than hurricane-force winds to introduce water into your cryogen vent.

All major vendors of superconducting MRI equipment provide cryogen vent discharge designs that are intended to keep wind-driven rain out of the vent pipe. Unfortunately, one of the most common quench pipe discharge details does not provide thorough protection, even at moderate wind speeds.

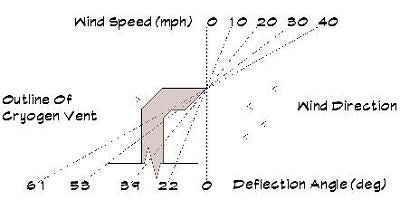

Many MRI vendor details on cryogen vent discharge indicate that the discharge is to be protected by a shield that prevents even horizontal rain or snow from entering the pipe. Another effective detail is to have the vent discharge turned to point downward toward the rooftop or other protected discharge area. Unfortunately, a significant number of installations have the cryogen vent discharge horizontally with nothing more than a 45˚ overhang protecting it from wind-driven precipitation.

|

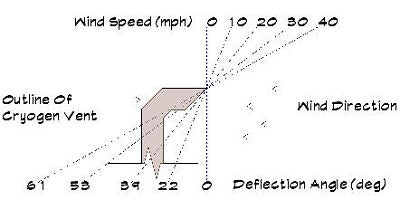

The illustration above indicates the approximate deflection of rain based on wind speed. At wind speeds above 25 miles per hour, a 45˚ overhang is defeated and rainwater may be able to enter the quench pipe. The larger the pipe or duct at the point of discharge, the greater the potential area for the water to enter the pipe. Snow, because of its much lower density as compared with water, is subject to significantly higher levels of deflection.

Hurricanes may represent the greatest single opportunity for significant quantities of water to enter a quench pipe, but rain doesn't have to come from the sky in buckets to threaten your MRI. Smaller quantities of water may accumulate over weeks or months and present similar threats.

The temperature inside the quench pipe for your superconducting MRI system is probably no warmer than about 50˚ F and could be significantly colder if your magnet has a high bleed rate into the quench pipe. Dark and cold inside the pipe, there is almost no opportunity for any accumulated water to evaporate. Without evaporation or leakage, every drop of water that enters the quench pipe will collect and accumulate.

While a half-liter of water wouldn't provide enough resistance to delay a magnet's quench, escaping cryogenic gasses may quickly drop the temperature in the quench pipe well below the freezing point. Assuming that a superconducting magnet system has a low bleed rate and the normal temperature in the quench pipe is above freezing, any power outage to the cold head often results in dramatically increased bleed rates. Escaping helium, at nearly 450˚ F below zero, can quickly turn any water into a solid block of ice on top of the pressure-relief valve. Magnets with high bleed rates may normally have quench pipe temperatures at or below freezing.

Although quenches are rare, they will occur at least once -- during decommissioning -- for each superconducting magnet. It is infrequent but not unheard of for a magnet to experience spontaneous or intentional quenches during its useful life, too. The protection of patients, staff, and your million-dollar MRI unit are all dependent on effective operation of your cryogen vent system.

Blockages in the quench pipe may lead to ruptures or failures of the pipe in a quench, allowing helium gas to blast into the magnet room, jeopardizing the safety of anyone within the room. Additionally, any increase in the pressure required to dislodge an ice block from atop the pressure-relief valve runs the risk of critically damaging the cryostat vessel that holds the liquid helium.

One superconducting MR model has a tolerance of only 4 lb of pressure between pressure-valve release and vessel failure. If a quench pressure buildup takes additional pressure of 4 lb, or more, to dislodge the ice blockage with the pressure-relief valve, the welds on the cryostat may be breached and the million-dollar magnet totaled.

What are facilities to do to protect against these risks to patients, staff, and equipment? It is recommended that facilities investigate the cryogen vent discharge for each superconducting MRI, and verify that the design and installation protects against wind-driven precipitation.

If it is found that the discharge does not adequately protect, contact the manufacturer and obtain its current cryogen vent details. Be sure to verify that those details provide the necessary protections for wind-driven precipitation. In the meantime, thoroughly investigate cryogen vent assemblies to look for signs of blockage and water accumulation.

These signs can include leaks, condensation, or scaling on cryogen vent piping. Have the vendor's engineer expose the outside of the pressure-relief valve during the next preventive maintenance to verify that no water has accumulated there. If there are any outward signs of water or ice buildup, have the vendor's engineer inspect the valve immediately.

As recommended by vendors of superconducting MR systems, basic cryogen vent inspections should be conducted at least annually to look for signs of wear or distress. Facilities should also take this opportunity to investigate the design details for cryogen vent discharge and check for any blockage, liquid or solid, in the pipe. Cryogen vent inspections are one component of a comprehensive MRI suite safety audit that investigates many other factors of suite design and its impact on safety and operations.

With hurricane season never more than a year away, each of us should take inspiration from our worries and fascination with the damage that any decent thunderstorm can inflict and take 30 minutes to look to how our own facility may be exposing us to internal disaster, or contact professionals who can help do this for us.

By Tobias Gilk

AuntMinnie.com contributing writer

November 16, 2006

Reprinted from www.mri-planning.com by permission of the authors. If you would like more information on any aspect of MR facility design or safety, please contact Robert Junk or Tobias Gilk at Jünk Architects.

Related Reading

MRI accident data: You don't know more than you think you do, October 27, 2006

DRA and MR patient throughput -- reimbursement cuts vs. unconventional wisdom, October 17, 2006

Burying an MRI: A tragedy in two acts, September 25, 2006

MRI safety in Canada, September 1, 2006

Magnet room finishes: Protect MRI safety and efficiency when building, August 14, 2006

Copyright © 2006 Jünk Architects, PC