Researchers have found a way to control high-pressure ultrasound to manipulate, move, or destroy structures noninvasively by using 3D-printed laser-generated focused ultrasound transducers, according to a new report in Applied Physics Letters.

The transducer's claim to fame is its control over photoacoustic waves, which are generated by lasers, potentially enabling the device to perform precise surgery, analyze materials properties, and perform laboratory research in microfluidics.

The researchers noted that surgeons already use focused ultrasound waves to destroy cancer cells, for example. The challenge has been aiming them.

"We have much better control of the photoacoustic wave, and the wave can be even designed such that it serves the purpose of a mechanical actuator," said investigator Claus-Dieter Ohl at Nanyang Technological University in Singapore, in a statement accompanying release of the study (Appl Phys Lett, October 24, 2016, Vol. 109:17, 174102).

The degree of control in the current study is enabled by 3D printing, the authors wrote. Earlier devices could produce only basic planar acoustic waves, which focus the energy on a single point.

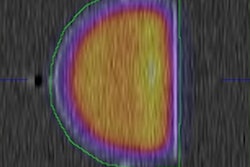

So-called laser-generated focused ultrasound transducers function by converting laser pulses into vibrations, the authors explained. The critical component is a glass surface that acts like a lens. When laser pulses hit the glass surface, which is coated in a thin film of carbon nanotubes, the heat causes the coating to expand rapidly, generating the vibrations that are needed to produce high-frequency acoustic waves.

But glass as a substrate material limits it to planar, cylindrical, or spherical shapes; more complicated shapes are difficult to make, they wrote.

The new 3D-printed product has a lens made of clear liquid resin, allowing it to be made in any shape -- and generate acoustic waves in any shape. This allows researchers to focus the waves at several points simultaneously, or control the wave phases and focus them at different points at different times, the group noted.

Being able to focus waves at different points and times enables the device to exert shear forces as well as sort, isolate, and manipulate droplets, particles, or living cells. This could be a powerful tool in the field of microfluidics, which requires strong and precise control of fluids, and the researchers are now using 3D-printed photoacoustic transducers to make actuators.