Video game technology is being used for much more than simply playing games these days. Case in point: A motion-sensing device for gaming consoles can now be used to help set x-ray exposure parameters, reducing repeat exams, according to a study published online in Pediatric Radiology.

Robert MacDougall from Boston Children's Hospital.

Robert MacDougall from Boston Children's Hospital.

The device would help radiologic technologists optimize x-ray image quality through proper positioning and exposure parameters before the patient has been exposed to radiation, lead author Robert MacDougall told AuntMinnie.com.

"We see this as having an impact on reducing repeat imaging, which saves hospital resources and saves the patient from unnecessary radiation exposure," he said. "I think it has potential to completely reshape how x-rays are acquired for the first time in a really long time."

First time around

The gradual shift from analog film-screen x-ray to digital technologies such as computed radiography (CR) and digital radiography (DR) has led to marked reductions in the amount of time it takes to acquire x-ray images, according to Benoit Scherrer, PhD, and Dr. Steven Don. At the same time, speeding up the acquisition process may be contributing to increases in repeat rates, which have gone up by approximately 5% for CR and 25% for DR (Pediatr Radiol, September 2, 2017).

Dr. Steven Don from Washington University School of Medicine.

Dr. Steven Don from Washington University School of Medicine.Other, more common reasons for repeat imaging are errors in positioning, patient movement, and imprecise exposure parameters. These potential mistakes may stem from an antiquated technologist workflow that was developed in an era of analog imaging.

"The way that x-rays are actually acquired today is the same way that they were acquired 50 years ago," MacDougall said.

Even if the technologist positions the patient correctly, there is plenty of time for the patient to stir as the technologist heads back to the shielded control area, MacDougall explained. Once there, the technologist has a restricted and distant view of the patient that is often not enough to effectively assess patient positioning.

What's more, manual techniques for setting x-ray exposure parameters require body part thickness measurements. Technologists can obtain this information by using physical calipers, which may intimidate children and necessitate subsequent cleaning, or by estimating exposure based on patient age, which is frequently unreliable due to variations in patient size.

"This process is completely fraught with potential for errors, and we sought to improve it," he said.

Benoit Scherrer, PhD, from Boston Children's Hospital.

Benoit Scherrer, PhD, from Boston Children's Hospital.Researchers have taken numerous measures to improve x-ray imaging, but the majority of these methods have focused on enhancing image quality after the patient has already been exposed to radiation. On the other hand, MacDougall and colleagues aimed to revamp the way in which the technologist acquires x-rays the first time around.

X-Vue

The researchers' efforts led to the development of an automated imaging device called X-Vue that is made up of four principal components:

- A 3D motion-sensing camera (Microsoft Kinect v2)

- A processing unit (Intel Next Unit of Computing)

- An application programming interface that communicates with the processing unit

- A user interface displayed on a monitor in the control room

Microsoft Kinect v2 is most often used as a motion sensor and facial and voice recognition device for the Xbox gaming console, but the technology has also been adapted for nongaming applications such as surgical manipulation of MR images. In this case, the 3D motion-sensing camera was mounted to the tube of a DR system (DigitalDiagnost, Philips Healthcare) with a custom 3D-printed mount.

The researchers developed proprietary software capable of using the video streams of the Microsoft Kinect v2 to calculate patient thickness and track patient motion and positioning in real-time, after performing a two-second automated calibration procedure.

The X-Vue device measures patient thickness in real-time to minimize radiation dose and displays information to ensure consistent image quality, according to MacDougall. The technologist can then adjust the x-ray exposure parameters for the most optimal image at the lowest radiation dose.

"It's all information that [technologists] need right now but can't easily obtain," he said. "I anticipate the learning curve to be very minimal because technologists intuitively know what they want; we're just providing it to them in a simple display."

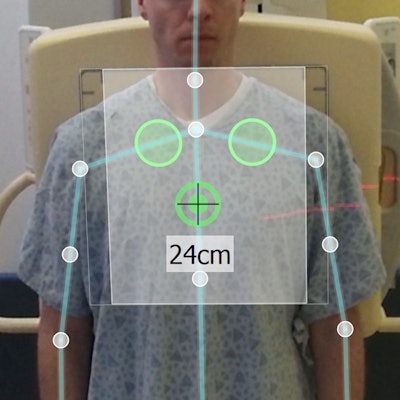

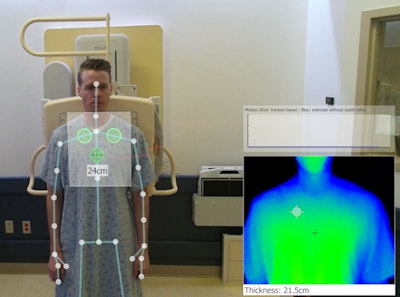

The X-Vue user interface displays an overlay of the three active exposure chambers (green circles) within the detector field (white box) on top of the patient. A depth map (bottom right) displays the body part thickness. A motion trace using skeleton tracking and optical flow sits above the depth map. Image courtesy of Robert MacDougall.

The X-Vue user interface displays an overlay of the three active exposure chambers (green circles) within the detector field (white box) on top of the patient. A depth map (bottom right) displays the body part thickness. A motion trace using skeleton tracking and optical flow sits above the depth map. Image courtesy of Robert MacDougall.Another noteworthy advantage of the device is that it is adaptable and vendor-neutral -- that is, the software can be used with different cameras and any CR or DR system, MacDougall said.

"The software itself is very modular. For example, we've already started testing it with different camera systems," he said. "We've recently started testing a camera called the CamBoard pico flexx from a company called PMD in Europe, and it's a much smaller camera."

Large-scale integration

X-Vue is also flexible in the sense that it can be used as a standalone product or be commercially integrated, though MacDougall believes there's a convincing argument for preferring commercial integration.

In the present system, there is a large display in the technologists' control room that is unused before the technologist acquires an image. A device like X-Vue can easily use that existing monitor real estate to display its augmented reality interface, which would allow the technologist to visualize parameters and make any necessary adjustments all on one screen, MacDougall said.

Beyond x-ray imaging, the current software and technology allow for applications in other modalities, including CT and MR, all of which are in the group's development road map, he said.

A prototype hospital test using X-Vue produced very positive feedback, according to MacDougall. In the coming months, the researchers will commence a much larger clinical test to quantify the reduction in repeat rates as well as radiation exposure.

"After we have the clinical results, we plan to seek other partners for large-scale integration of the device," he said. "We see this as something that is going to happen once technologists understand the impact of having this information."