Presurgical planning on 3D-printed models allowed researchers from China to perform liver transplants with more accuracy and efficiency than standard surgical planning methods -- ultimately speeding up operation times and reducing patient costs, according to an article recently published online in Liver Transplantation.

The group, led by senior author Dr. Zhong Lin from Shanghai General Hospital, planned liver transplants for 30 pediatric patients using individually tailored 3D-printed liver models for 10 patients and conventional methods for 20 patients (Liver Transpl, February 15, 2019).

Recent advancements in 3D imaging have greatly enhanced the visualization of intricate liver structures, the authors noted. Clinicians have used computer software to interact with 3D CT and MRI scans in real-time, which has helped surgeons improve their understanding of liver anatomy as well as their operative precision.

But this method has several major drawbacks, including limited depth perception and unreliable surface markers, which still make it challenging for clinicians to plan liver transplants for complex cases.

Many 3D printing case studies and small-scale 3D printing trials have demonstrated the potential of this technology to help clinicians overcome some of the pressing challenges, which could point to patient-specific 3D-printed models as the next step in presurgical planning and intraoperative guidance.

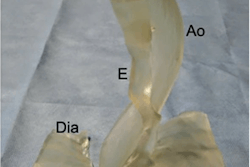

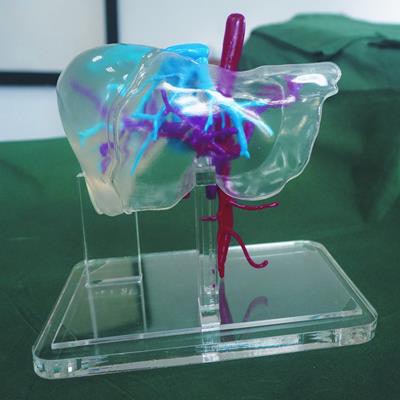

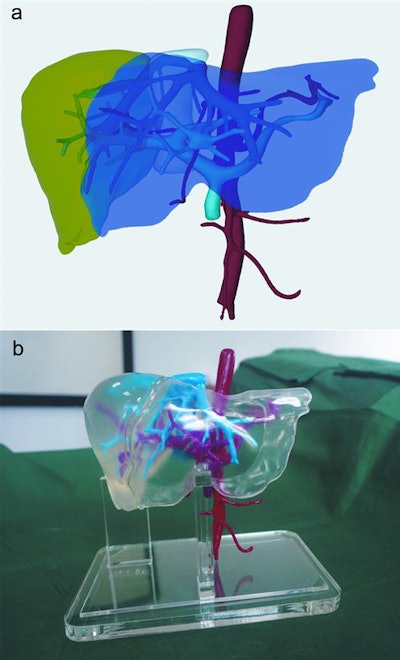

To determine the benefits of using 3D-printed models to plan and guide liver transplants, Lin and colleagues acquired the CT or MRI scans of the liver donors and recipients. Then they turned the 2D images into 3D virtual models with computer software, converted these 3D image files into stereolithography format, and imported the files into a 3D printer (Lite 300, UnionTech). They followed this process to create patient-specific 3D-printed liver models that were color coded and had a pliable texture resembling liver tissue.

3D virtual liver model (a). 3D-printed liver model (b). Image courtesy of Dr. Zhong Lin.

3D virtual liver model (a). 3D-printed liver model (b). Image courtesy of Dr. Zhong Lin.For the liver donors, the researchers found that planning the transplantations using the 3D-printed liver models reduced the average operation time to 2.3 hours -- a statistically significant drop from the standard three hours (p < 0.001). They also calculated the inpatient expenses for living donor liver transplantations and found that the costs were 17.1% lower for cases that relied on 3D-printed models (p = 0.03), not including the cost of the model.

Similar time and cost benefits applied to the liver recipients, although not to a statistically significant degree. In addition, both liver donors and recipients whose cases involved 3D-printed models had fewer postoperative complications (20%), compared with those who received standard treatment (25%).

Still, the authors acknowledged some disadvantages to relying on 3D printing for liver transplants, namely the manufacturing fees and long processing times; it required approximately 6,000 yuan ($893) and 48 hours to make an open-faced 3D-printed liver model.

Continued development of 3D printing technology may help overcome these barriers, and extending the application of 3D-printed models to train novice surgeons and educate patients can further increase their overall value, Lin and colleagues noted.

"The 3D printing liver models and abdominal cavity in our study may be a foundation of 3D bioprinting in the future," they wrote.