Researchers are highlighting their approach to 3D printing, which uses ultrasound waves to create objects from sonically cured inks. Their results were published December 7 in Science.

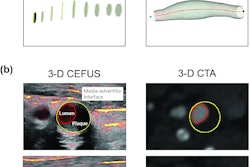

A team led by Xiao Kuang, PhD, from Harvard Medical School found that its ultrasonic 3D printing method -- deep-penetrating acoustic volumetric printing --successfully created anatomical structures such as the liver, kidney, and vessel networks.

“The deep penetration of focused ultrasound waves allows the volumetric fabrication of opaque [nano]composites and printing through centimeter-thick tissues that are not attainable through state-of-the-art light-based printing techniques,” the Kuang team wrote.

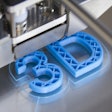

Volumetric printing is a 3D-printing technique that the researchers noted can build objects faster and with better surface quality than layer-by-layer printing methods. Light is typically used to trigger the combining of molecules for material building in optically transparent inks, a process called photopolymerization.

However, the researchers pointed out that material choices are limited here due to several factors. These include light scattering by the inks, the presence of functional additives within the inks, and light-blocking by already cured portions of built materials.

Kuang and colleagues suggested that ultrasound could be the key to overcoming these limitations since ultrasonic waves can penetrate deeper into materials. They developed their method by using focused ultrasound waves and sono-ink, which uses a heat-responsive adaptive acoustic absorber to form a viscous gel that prevents streaming flow while starting a heat-triggered polymerization.

In deep-penetrating acoustic volumetric printing, focused ultrasound waves with deep-penetrating acoustic energies are sent to the local region at up to 64 mm. The energies are delivered with pressures up to several tens of megapascals, the researchers reported. From there, the small oval-shaped ultrasonic focal zone is further narrowed by the nonlinear acoustic propagation effect at high acoustic pressure. This makes way for fast, high-resolution printing, the team wrote.

“Consequently, deep-penetrating acoustic volumetric printing allows us to print geometrically complex materials precisely and volumetrically, even through nontransparent and optically scattering materials,” the group added.

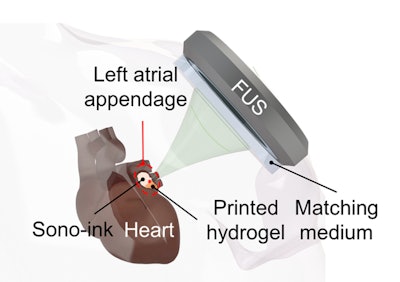

A scheme shows the minimally invasive left atrial appendage closure by delivering and solidifying sono-inks in the entire atrial appendage volume. Researchers highlighted the success of their deep-penetrating acoustic volumetric printing method, which uses focused ultrasound. Image courtesy of Xiao Kuang.

A scheme shows the minimally invasive left atrial appendage closure by delivering and solidifying sono-inks in the entire atrial appendage volume. Researchers highlighted the success of their deep-penetrating acoustic volumetric printing method, which uses focused ultrasound. Image courtesy of Xiao Kuang.

The researchers found that deep-penetrating acoustic volumetric printing allowed for objects to be quickly printed from nanocomposite materials at a millimeter scale and several centimeters deep in opaque media.

The team tested its method on ex vivo tissues infused with sono-ink. It found that the method was successful for in situ fabrication of artificial bone and of a left atrial appendage closure.

“After treatment, the cured hydrogels completely occluded the left atrial appendage and bonded well with the tissue wall, which could tolerate reasonable distortions that mimicked the heart beating,” it wrote.

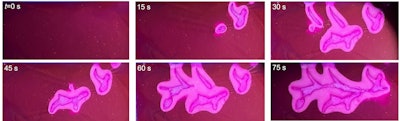

The researchers also successfully 3D printed anatomical structures such as vessel networks, a hand, and a hollow heart-shaped model through porcine kidney tissue, and lattice structures through porcine liver tissues.

A 2D vessel-like network (75 mm by 25 mm) was printed using confocal deep-penetrating acoustic volumetric printing in 80 seconds. Image courtesy of Saud Belal.

A 2D vessel-like network (75 mm by 25 mm) was printed using confocal deep-penetrating acoustic volumetric printing in 80 seconds. Image courtesy of Saud Belal.

The self-enhancing sono-ink design can be generalized for different systems, the study authors wrote. They added that this feature can expand the materials library for acoustic printing techniques.

The study can be found in its entirety here.