Researchers at the National Centre for Nuclear Research (NCBJ) in Swierk, Poland, have secured a patent for the use of 3D printing technology to increase production of molybdenum-99 (Mo-99) for medical imaging.

Physicist Paweł Sobkowicz and colleagues at the NCBJ's Nomaten Centre of Excellence received the patent from the European Patent Office on November 30. The patent covers a method for preparing low enriched uranium-235 (Mo-99's parent isotope) for irradiation by neutrons using spatial printing by laser powder sintering.

"3D printing techniques have been known for a long time, but so far they have not been used to produce uranium targets for neutron irradiation in reactors. However, we believe that this way of producing targets can have a number of advantages," Sobkowicz said in a statement released by the NCBJ.

Mo-99 is produced by irradiating uranium-235 (U-235) in nuclear research reactors, such as Poland's Maria nuclear reactor. Only five nuclear reactors in the world are capable of producing Mo-99. When production problems occur at these reactors, the isotope supply may be disrupted worldwide.

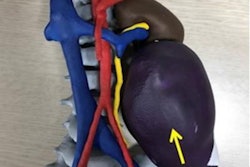

Irradiation container placed in the MARIA reactor facility in Poland. Image courtesy of the National Centre for Nuclear Research.

Irradiation container placed in the MARIA reactor facility in Poland. Image courtesy of the National Centre for Nuclear Research.Once Mo-99 is produced, it is shipped to medical facilities where it emits technetium-99m (Tc-99m) as it decays; this daughter isotope is used in a majority of nuclear medicine diagnostic examinations. More than 85% of all nuclear medicine diagnostic examinations use Tc-99m. The Polish team's method could increase the supply of Tc-99m by using a 3D printing technique to irradiate uranium 235 (U-235) targets so that more Mo-99 is produced.

Typically, to ensure that as many U-235 nuclei as possible are converted to Mo-99, targets are prepared from a dispersion of uranium or its oxide or silicide to aluminum plates. But this process doesn't leave much room for optimization, so the researchers developed a way to prepare the uranium targets using laser powder sintering, a technique that melts a thin layer of metal powder on the working platform inside the reaction container.

After the first layer is fixed, the platform is lowered slightly and the next layer of powder is applied. The key to the process is that 3D printing allows the researchers to optimize the shape of the uranium targets so that heat is more effectively dissipated, according to Sobkowicz and colleagues: The uranium targets heat up less during irradiation by neutrons, and this increases the U-235 content.

"As a result, more molybdenum-99 could be produced per exposure," Sobkowicz explained.