Have you ever wanted to improve a device you use every day? It's now easier thanks to the magic of 3D printing. Researchers who modified a compression paddle for CT-guided fluoroscopy studies described how they did it in a May 15 article in the American Journal of Roentgenology.

The group of radiologists from Brigham and Women's Hospital used 3D printing to modify F-Spoon, a bowel compression paddle that's been around since 1989. They were able to modify and print a new version of the device that is easier to use for CT-guided interventional procedures, while also enabling radiologists to keep their hands out of the x-ray beam.

In addition to describing their accomplishment, the researchers posted the digital file they created on the internet for anyone to download and use (AJR, May 15, 2017).

Building a better F-Spoon

F-Spoon is a commercially available device that was created by Dr. Francis Scholz, a radiologist at Lahey Hospital and Medical Center in Burlington, MA. It resembles an oversized spoon connected to a large handle, and it was originally devised for use in palpating the gastrointestinal (GI) tract during fluoroscopy studies such as barium enema procedures.

At Brigham, radiologists some time ago modified F-Spoon by cutting a keyhole-shaped notch in the spoon that made it better for guiding needle interventions during CT fluoroscopy studies. By inserting a needle into the keyhole notch, radiologists could compress the abdomen to move bowel loops aside while inserting needles, and they could also keep their hands out of the x-ray beam.

However, the Brigham team felt they could build an even better F-Spoon by making it easier to handle and manipulate. So they turned to 3D printing, according to Dr. Paul Shyn, a co-author on the AJR paper.

"We thought this might be something where if we could make a digital file, we could modify and print a better version," Shyn told AuntMinnie.com.

Cardiovascular radiologists at Brigham and Women's were already using 3D printing to make 3D models of anatomic structures such as heart valves that could be used to plan heart surgeries. The researchers were able to tap into that experience as they planned their device.

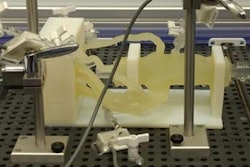

First, they performed a CT scan of the original F-Spoon and imported the file into a computer-aided design (CAD) software application. They used the software to make several modifications based on feedback they had received from physicians, such as changing the device's handle to make it easier to use with either hand, and narrowing the device's neck to make it easier to fit into an ultrasound probe cover -- an important consideration for sterile interventional environments. The CAD file was then converted to the stereolithography (STL) format and output to a 3D printer.

Original F-Spoon (top) with arrow indicating modified keyhole cut into device for needle placement. 3D-printed paddle (below) with arrows showing handgrip and curved armrest that allows ambidextrous use (far right). All images courtesy of AJR.

Original F-Spoon (top) with arrow indicating modified keyhole cut into device for needle placement. 3D-printed paddle (below) with arrows showing handgrip and curved armrest that allows ambidextrous use (far right). All images courtesy of AJR.Selective laser sintering was used for printing, with nylon powder as the printing material. The researchers had access to a 3D printer with a long print bed, which meant the entire device could be printed in one piece, without structural weaknesses that can result from having to combine two separately printed pieces. Once the device was printed, it was coated with multiple applications of acrylic spray paint to seal microstriations from the 3D printing process and make it easier to disinfect.

But the proof is in the pudding, so the researchers decided to test their 3D-printed compression paddle by using it in 21 CT fluoroscopy-guided procedures, consisting of 18 biopsies, two abscess drainages, and one liver microwave ablation. They tracked how the device was used and whether the interventional procedure would have been possible without it.

Ultimately, 15 procedures were deemed "questionably feasible" but difficult to perform without the paddle, four were rated as "not feasible" without the device, and two were categorized as feasible without the device but facilitated by the use of it. A particular benefit was the ability to use the paddle to steer the needle by applying pressure against it from inside the keyhole.

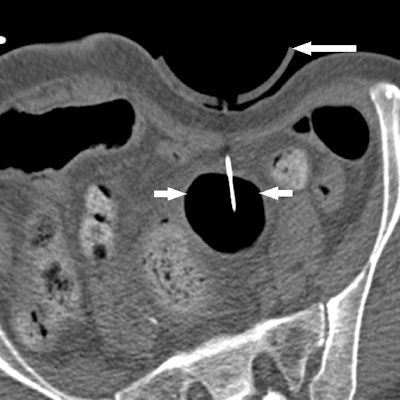

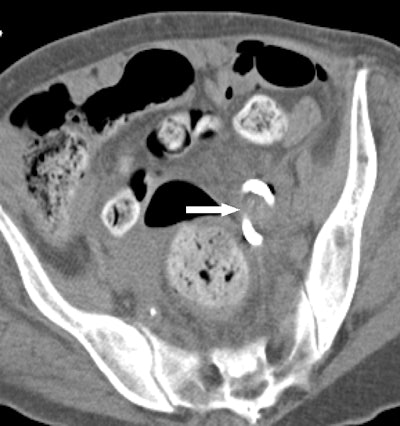

Series of images from an 88-year-old woman with perforated diverticulitis and left pelvic abscess treated with CT-guided percutaneous catheter drainage. CT image above shows pelvic abscess (long white arrow) containing air and fluid. Intervening bowel loops (short white arrows) are present anteriorly, iliac blood vessels laterally, and bone posteriorly. No safe, unobstructed access was available.

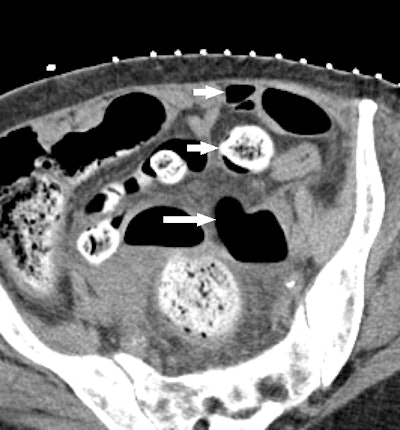

Series of images from an 88-year-old woman with perforated diverticulitis and left pelvic abscess treated with CT-guided percutaneous catheter drainage. CT image above shows pelvic abscess (long white arrow) containing air and fluid. Intervening bowel loops (short white arrows) are present anteriorly, iliac blood vessels laterally, and bone posteriorly. No safe, unobstructed access was available. Image obtained during intermittent CT fluoroscopy shows displacement of bowel loops by 3D-printed compression device (long arrow) to give needle and guidewire access to pelvic abscess (short arrows).

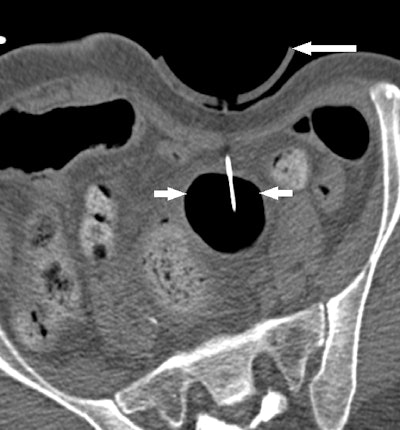

Image obtained during intermittent CT fluoroscopy shows displacement of bowel loops by 3D-printed compression device (long arrow) to give needle and guidewire access to pelvic abscess (short arrows). CT image obtained after procedure confirms placement of loop catheter (arrow) and complete drainage of abscess.

CT image obtained after procedure confirms placement of loop catheter (arrow) and complete drainage of abscess.Because the goal of the original F-Spoon was to help radiologists avoid radiation while guiding interventional procedures, the Brigham group also measured the amount of radiation dose at the site of the skin incision point for the two abscess drainages, calculating a mean radiation dose of 14.95 mGy. For point of reference, the group calculated a mean radiation dose of 0.31 mGy to the operator's finger, just 2% of the mean dose recorded at the incision point.

The success of the experiment led to internal discussions within the Brigham group of whether to try to commercialize the 3D-printed paddle. Ultimately, however, they chose to make the CAD file available on an open-source basis. It was a decision supported by Scholz, the inventor of the original F-Spoon.

"This isn't a device that will be sold at Walmart where you will sell 100,000 of them," Shyn said. "There is a very small target market for it."

But the lesson of the modified F-Spoon is bigger than just one compression paddle. Radiology departments could follow a similar path and use 3D printing to customize any device they use.

Shyn admitted that it's easier from a regulatory point of view to create 3D-printed devices that are used externally, such as the 3D-printed F-Spoon, than those used internally, which might carry more risk to the patient.

But the dissemination of 3D printing expertise throughout healthcare is putting modified devices within reach of anyone with an idea and a 3D printer.

"I think there are bound to be other areas where doing something like this could work," Shyn said.