Researchers from Harvard University have developed a 3D printing technique that allows clinicians to determine the ideal size of replacement heart valves for transcatheter aortic valve replacement (TAVR), according to a recent article in the Journal of Cardiovascular Computed Tomography.

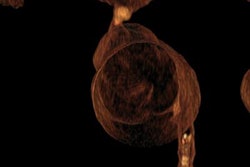

The group, led by first author and research fellow Ahmed Hosny, created a software program that uses parametric modeling to generate virtual 3D models of heart valves based on imaging data from CT scans. They used this software to make personalized 3D-printed models of the heart valves of 30 patients who had previously undergone a TAVR procedure.

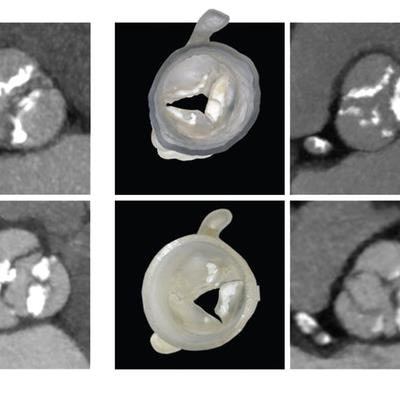

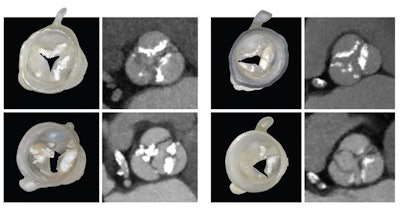

Four distinct 3D-printed heart valve models shown next to their corresponding CT scans, with calcified deposits in white. Image courtesy of the Wyss Institute at Harvard University.

Four distinct 3D-printed heart valve models shown next to their corresponding CT scans, with calcified deposits in white. Image courtesy of the Wyss Institute at Harvard University.The researchers also 3D printed a custom sizer device wrapped with pressure-sensing film that could expand and contract inside the 3D-printed heart valve models and, ultimately, calculate the size of the artificial valve needed for each patient. Using this process, Hosny and colleagues were able to predict whether or not a replacement valve would leak with a sensitivity of 60% and a specificity of 73% (JCCT, October 2, 2018).

"Our integrative 3D printing and valve sizing system provides a customized report of every patient's unique aortic valve shape, removing a lot of the guesswork and helping each patient receive a more accurately sized valve," corresponding author James Weaver, PhD, said in a statement.

The team's leaflet modeling software and 3D printing protocol are available online for free download.