3D-printed nasopharyngeal swabs perform just as well as traditional flocked swabs used to collect nasal secretions for COVID-19 tests, according to results of a clinical trial scheduled to be presented at the upcoming virtual RSNA 2020 meeting.

In a head-to-head trial conducted on 291 patients at three institutions, the 3D-printed swabs yielded statistically identical results to the flocked swabs, according to researchers led by Summer Decker, PhD, of the University of South Florida (USF).

"The results were overwhelmingly positive," Decker said in a statement from the RSNA. "The clinical trial showed that the 3D nasal swabs performed as well as -- or, in some cases, better than -- flocked swabs."

In an attempt to help with the widespread shortage of swabs early in the coronavirus pandemic, the radiology department at USF Health in Tampa set out in March to design and create nasopharyngeal swabs using a point-of-care 3D printer. Collaboration with other departments, as well as Todd Goldstein, PhD, of Northwell Health System in New York City, resulted in testing of three designs.

A final prototype, which was produced using surgical-grade resin and a FormLabs 3D printer, was then sent to infectious disease specialists at both USF and Northwell for validation testing, according to the researchers.

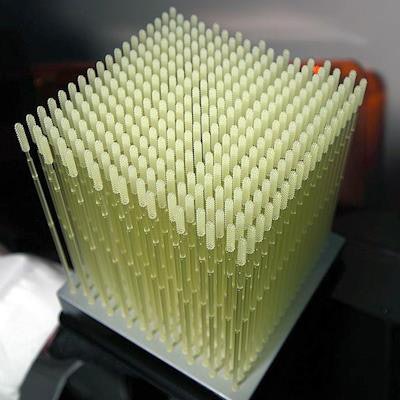

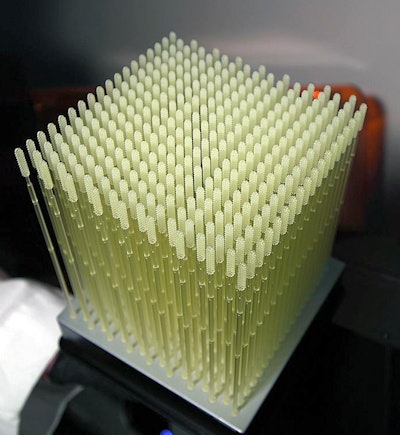

3D-printed swabs. Image courtesy of the RSNA.

3D-printed swabs. Image courtesy of the RSNA.Depending on the printer, the 3D printing process takes up to 15 hours. Next, the printed swabs are rinsed in isopropyl alcohol, cured, and inspected for defects by hand. In the last step, a member of the hospital's infectious disease team examines each swab before it is sterilized in an autoclave and packed in a test kit, according to the researchers.

A clinical trial was then performed at Tampa General Hospital, Northwell Hospital, and Thomas Jefferson University Hospital in Philadelphia to directly compare the performance of 3D-printed swabs and flocked swabs for COVID-19 testing.

After the successful trial, Tampa General Hospital has adopted the 3D-printed swab as its standard of care and has begun printing more than 300 swabs a day for the hospital and its affiliated care centers. So far, USF Health has printed more than 100,000 3D nasopharyngeal swabs, the researchers said.

What's more, hospitals around the world have used the 3D files to print tens of millions more swabs for point-of-care use, according to Decker, who is director of 3D clinical applications for the department of radiology in the USF Health Morsani College of Medicine and Tampa General Hospital. USF has filed for a provisional patent on the 3D nasopharyngeal swab, and it provides the design files and clinical data for free to hospitals, clinics, and licensed medical device companies around the world.

Decker also noted that the project was initiated and developed through collaborations established in the RSNA 3D Printing Special Interest Group.

"This project shows novel ways that radiology departments around the world can directly impact hospitals and clinical care during a crisis like COVID-19," she said.