Virtual 3D models created from CT data can be utilized for surgical planning and providing patient-specific treatments for complex acetabular fractures, according to research published online February 18 in JAMA Network Open.

A team of researchers led by Dr. Frank Ijpma, PhD, of the University Medical Center Groningen in the Netherlands shared results from a case series of 10 acetabular fracture patients who were treated using a "fast-track" surgical procedure. The group found that their approach, which involves 3D virtual surgical planning and manufacturing patient-specific osteosynthesis plates and drilling guides, was feasible and yielded good clinical outcomes.

"Fast-track personalized surgical treatment could open a new era for the treatment of complex injuries," the authors wrote.

Optimally reconstructing the articular surface during acetabular fracture surgery lowers the risk of osteoarthritis and subsequent need for total hip arthroplasty, according to the researchers.

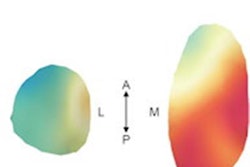

"However, no one-size-fits-all osteosynthesis plate is available owing to differences in fracture patterns and variations in pelvic anatomy," Ijpma and colleagues wrote. "Currently, osteosynthesis plates need to be manually contoured intraoperatively, often resulting in inadequate reduction and fixation of the fractured segments."

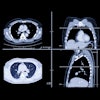

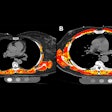

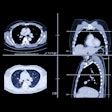

As a result, the researchers sought to explore the possibility of fast-track virtual surgical planning and patient-specific osteosynthesis. In this process, a 3D model is initially created from a patient's preoperative CT scan using version 19 of the Mimics Medical software (Materialise).

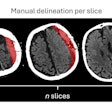

After each fracture fragment is virtually reduced on the model to its anatomic position, a multidisciplinary team of pelvic surgeons, technical physicians, and an engineer discuss the surgical plan, screw trajectories, and osteosynthesis plate design.

Planned based on the 3D model, the titanium osteosynthesis plates are tailored to both the patient's pelvis shape and the fracture type. These plates are designed using version 11 of the 3-Matic software (Materialise), version 2017 of Solidworks Professional software (Dassault Systèmes Solidworks), and the Geomagic package for Solidworks (3D Systems).

The custom-made titanium plates and drilling guides were manufactured, sterilized, and clinically applied within four days of patient trauma, according to the authors. In the 10 patients, this individualized, multidisciplinary workflow-enabled accurate reconstruction of the acetabulum and fixation of the fracture fragments, the researchers concluded.

"Moreover, none of the osteosynthesis plates required intraoperative contouring maneuvers and all the screws could be placed accurately using the drilling guides," they wrote.

| Fracture reduction results from using fast-track personalized treatment method | ||

| Preoperative measurement on CT | Postoperative measurement on CT | |

| Median interquartile range (IQR) gap | 20 mm | 3 mm |

| Median IQR step-off | 5 mm | 0 mm |

Delving further into the data, they found a mean difference of 14.6 mm between the preoperative and postoperative gap, as well as a mean difference of 5.7 mm in step-off. Also, the median IQR difference in screw direction between the planning and actual surgery was only 7.1 degrees, according to the researchers.

The fracture reduction was graded by CT-based criteria as perfect in three patients and good in seven patients. At one-year follow-up, all patients retained their native hip and reported good functioning, according to the researchers.

The study's concept of personalized fracture care is very interesting, as it could be broadly applicable to various other surgical subdisciplines, noted Dr. Geertje Govaert, PhD; Dr. Falco Hietbrink, PhD; and Dr. Koen Williamsen of University Medical Center Utrecht in the Netherlands in an accompanying commentary.

"However, to further determine whether fast-track osteosynthesis is a gimmick for the happy few or the future for trauma surgery, we need well-designed and sufficiently powered prospective studies that compare patient-specific osteosynthesis implants targeting clinical outcomes and patient safety with a transparent impression of the costs," they wrote.