Surface coils are an integral part of any MRI system. There are broad differences in configuration, design, and performance levels, and coils continue to evolve with scanner technology enhancements. Configurations can include knee, lumbar, head, shoulder, wrist, spine, torso, and extremity-type coils. MRI coil designs have evolved from linear, to quadrature, to phased-array, to multichannel configurations. However, as performance and complexity of surface coils increase, so do service-related expenses.

MRI coil failures are costly when you factor in service-event expenses, lost revenues from canceled procedures, and costs associated with patient rescheduling, potential delayed diagnosis, and patient/employee satisfaction. One MRI coil original equipment manufacturer (OEM) states that one service event can be expected to occur on MRI coils every two years. In addition to the cost of replacing and repairing a failed MRI coil, lost revenues can add up to more than $3,200 per day.

Most MRI coil failures occur due to one of three reasons: frequent use, failure due to impact, or improper use. As with any electronic device, frequent use of a product can cause failure over time. Electronic components break down, poor solder connections fail, flexible components experience metal fatigue and become brittle, and system transients (nonstandard operating currents/voltages) expose design limitations.

Failures due to impact, such as when the coil is dropped or roughly handled, are the second most frequent cause of coil replacement or repair. Finally, improper use of MRI coils also drives failures. One example of improper use is trying to use a transmit/receive (T/R) coil in conjunction with a large body coil. This will cause the electronics in the T/R coil to break down due to an increase of focused energy levels from the body coil.

Although electronic failures caused by component degradation are out of a customer's control, failures due to impact can be minimized. Because of their delicate design, MRI coils must be handled with great care. Failures after mishandling that are mechanical in nature are often obvious, but dropped coils often have electrical failures that can include broken coil loops, damaged cables, solder joint failures, loose components, and damaged connector pins.

Additionally, coil connectors usually fail when forcefully pulled from the system connection port. Operators should use extreme care when disconnecting a surface coil from the scanner port because MRI coil connections usually cannot be repaired onsite. Appropriate use and care of the equipment will greatly reduce the occurrence of failures.

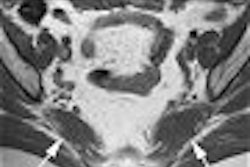

Typical examples of failures and specific problems:

|

||||||||||||||

When a coil does exhibit a problem, many OEMs do not offer MRI coil repair to customers. Typically, they provide an exchange option that is either a covered expense (through a warranty or a service-contract agreement) or a noncovered expense, such as potential misuse and abuse of the device, which has flat pricing.

An exchange is usually the only offered option, and the associated fees are fixed -- regardless of the type of service required. An OEM field engineer generally exchanges the damaged coil for an MRI coil from the manufacturer's inventory. The defective MRI coil is sent to the OEM's repair facility, where it is usually repaired or refurbished, then returned to the OEM's inventory. This practice assists in reducing system downtime, but it is also the most expensive method (and the most profitable to the OEM).

Independent MRI coil-repair vendors are an alternative to OEM offerings. These vendors will offer the use of the same or a comparable loaner coil for the duration of the repair. Loaners are shipped next-day to the site, ensuring that downtime is minimal. Typical turnaround time on a repair is three to 10 business days. And if the failed coil proves nonrepairable, these vendors can offer same-exact, refurbished replacement coils at prices far lower than an OEM.

For example, our organization recommends two vendors to its clients for MRI coil repair and replacement. One is a major medical manufacturer that produces surface coils used on other manufacturers' MRI equipment. The other is an autonomous subsidiary of an MRI manufacturer that has specialized in coil repair for more than 10 years. Typically, these vendors offer savings of $3,000 to $20,000 over the OEM replacement price by repairing the coil.

The key to a successful repair is accurate communication of the problems that are occurring with the device. This not only helps expedite the repair process, but also ensures that the particular problems experienced while using the MRI coil are addressed.

For example, a T/R driver-fault error can occur due to improper or poor seating of the MRI coil connector in the scanner port. If the connector is worn mechanically, it may not be apparent to the MRI coil-repair vendor, but proper communication of the problem will lead to appropriate servicing.

By Judy Kujawa and Dennis Durmis

AuntMinnie.com contributing writers

April 20, 2005

Judy Kujawa is director of equipment resources for Thermo USCS, a Brookfield, WI-based business unit of Thermo Electron that provides asset management services to hospitals, healthcare facilities, and laboratories. Dennis Durmis is director of marketing, multivendor service (MVS), for medical device developer Medrad of Indianola, PA, an affiliate of Berlin-based Schering. The MVS group supports MR coils and ultrasound probes from a variety of OEMs.

Related Reading

Fighting fear, uncertainty, and doubt in asset management, August 9, 2004

Frequency of repairs for cardiac cath labs compared, June 21, 2004

Repair charges in five modalities show stability over three-year span, March 29, 2004

Ultrasound transducer replacement costs, February 10, 2004

Copyright © 2005 Thermo USCS